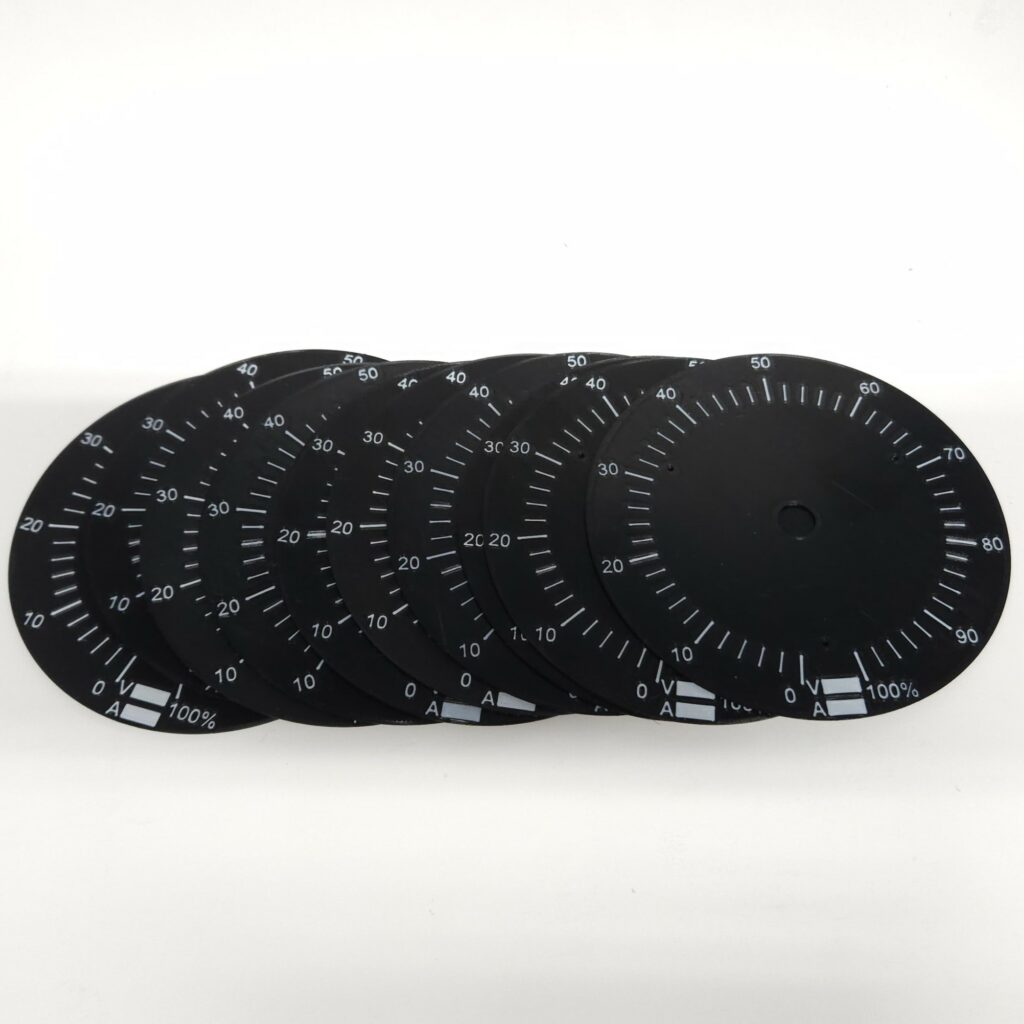

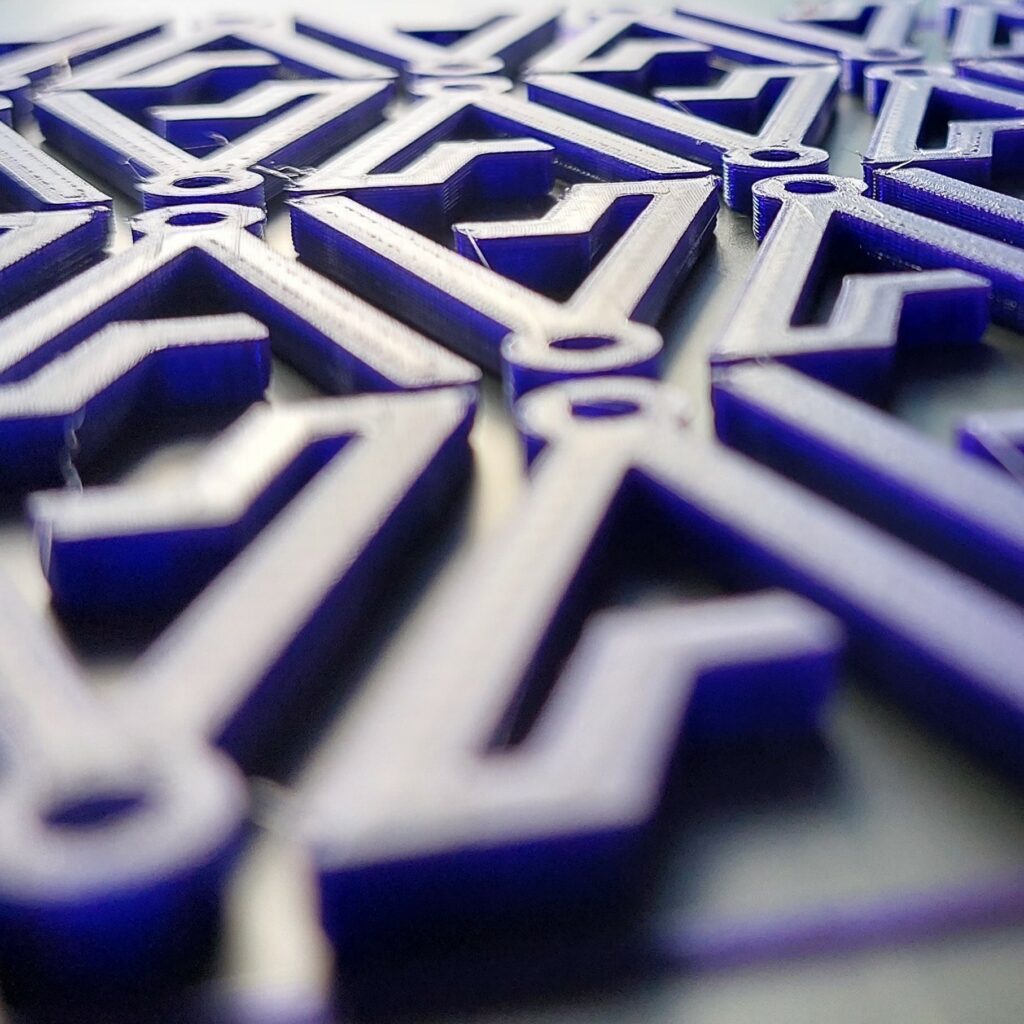

Production parts

No molds, no minimum order quantities and just in time delivery are just some of the advantages Actualizings can provide by using 3D-printing beyond the prototyping stage.

3D-printing for production parts

Lower cost

Working with us avoids the expensive up front costs related to using molds, storage and shipping.

Flexible production volumes

Production of 1 to 1000's of parts, 3D-printing allows low overhead for production of new parts while retaining the ability to quickly scale up. Parts can be delivered all at once or spread out over time allowing you to update to new design iterations whenever the need arises.

inserts and assemblies

Nuts, bolts, thread inserts, PCB's, weights, ... A range of objects can be embedded in 3D-printed parts to meet specific technical requirements.

Material flexibility

Parts can be produced in a range of colors and exotic materials including but not limited to PETG, ABS, PA-6, Polycarbonate, ... But also composite materials with metal, wood, ... fibers.

Why choose us?

Production 3D-printed parts work best when designed for 3D-printing. Actualizings has the design and production chops to help you bring your parts to life and ensure they are optimized for 3D-printing.

Interested in our services?

Feel free to reach out to for a quote, to set up a conversation on how we can best help you with our services or any other information at: